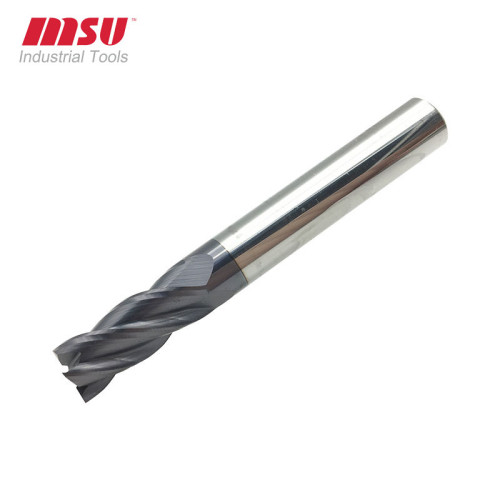

HRC45- 4 Flute Square Carbide End Mill

- Model

- D1mm-20mm

Item specifics

- Material

- Solid Carbide

- Internal Cooling

- Without

- No of Cutting Flute

- 4 Flute

- Type

- Flattened

- Coating

- TiAIN/Altin

- Cutting Direction

- Right - Hand

- Helix Angle

- 35°

- Precision

- ±0.01

- Workpiece

- Carbon Steel/ Alloy Steel/Grey Cast Iron

- Application

- Milling

- Cutting Diameter

- 1mm-20mm

- Full Length

- 50mm/75mm/100mm/150mm

Review

Description

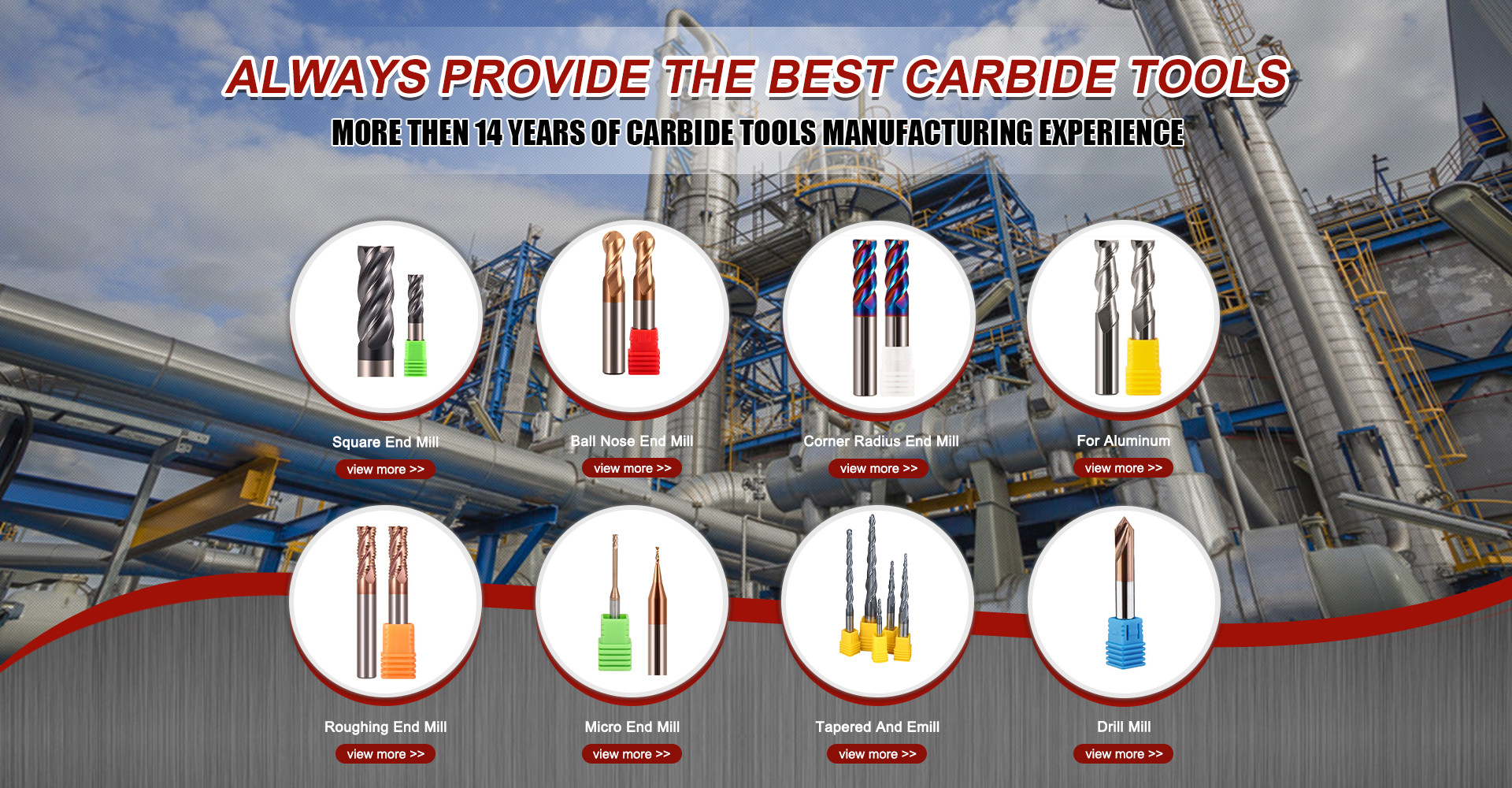

4 Flute Carbide End Mill Cutters

|

Description

|

Square End Mills Carbide 4 Flute China CNC End Mill Cutters Manufacturer

|

||

|

Hardness

|

HRC45 (HRC55/60/65 Available)

|

||

|

Coating

|

AlTiN,TiAlN,TiSiN,TiN,DLC,NANO

|

||

|

Helix Angle

|

10°/15°/35°/38°/42°/45°

|

||

Workpiece | Carbon Steel/ Alloy Steel/Grey Cast Iron/ Nodular Cast Iron | ||

Application | Side Face/ Step Shoulder/ Straight Slot /Deep Slot | ||

1. Premium carbide grade for making carbide endmill cutters. 2. Cutting edge over center, easy chip removal, no built-edge. 3. AlTiN Coating, super wear resistance and heat resistance. 4. Chamfer Shank, easy operation, high precision, end mill no vibration. All End Mills are made by 5 Axis CNC machines such as ANCA/Walter, the end mills come to be high precision, long working life, high efficiency. | |||

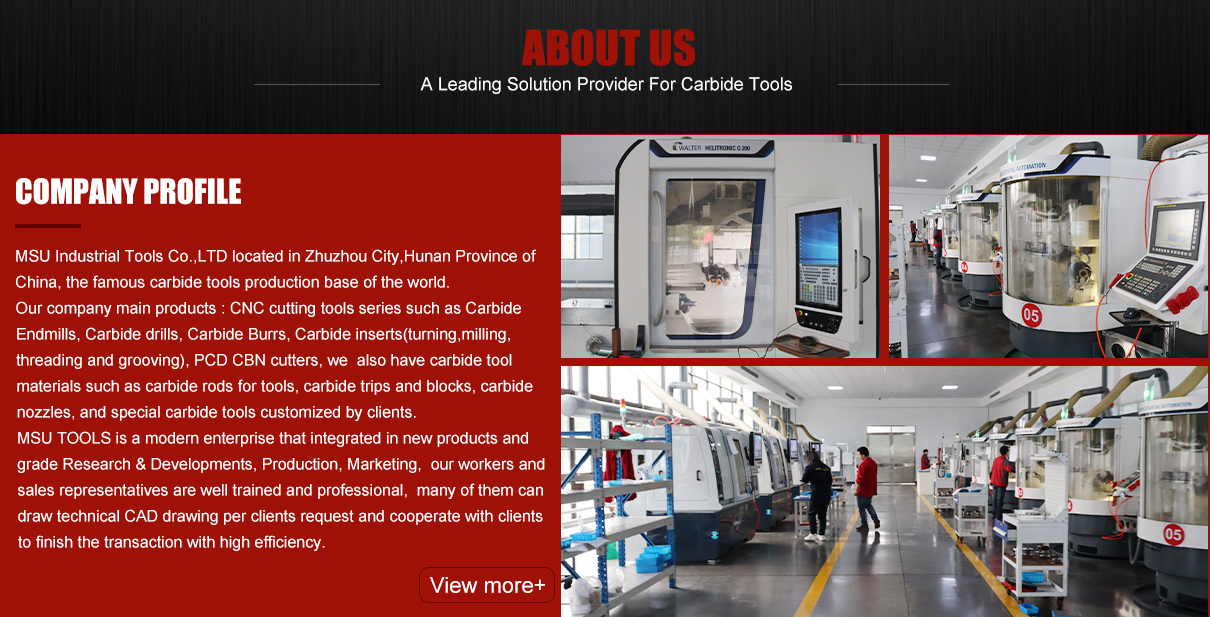

Our Advantages

Advanced CNC grinding machines

With 5-Axis automatic CNC grinding machines from abroad

4 Michael Deckel from Germany

3 ANCA from Australia

1 TTB from Australia

Top Work from Taiwan

Guarantee high precision and good performance.

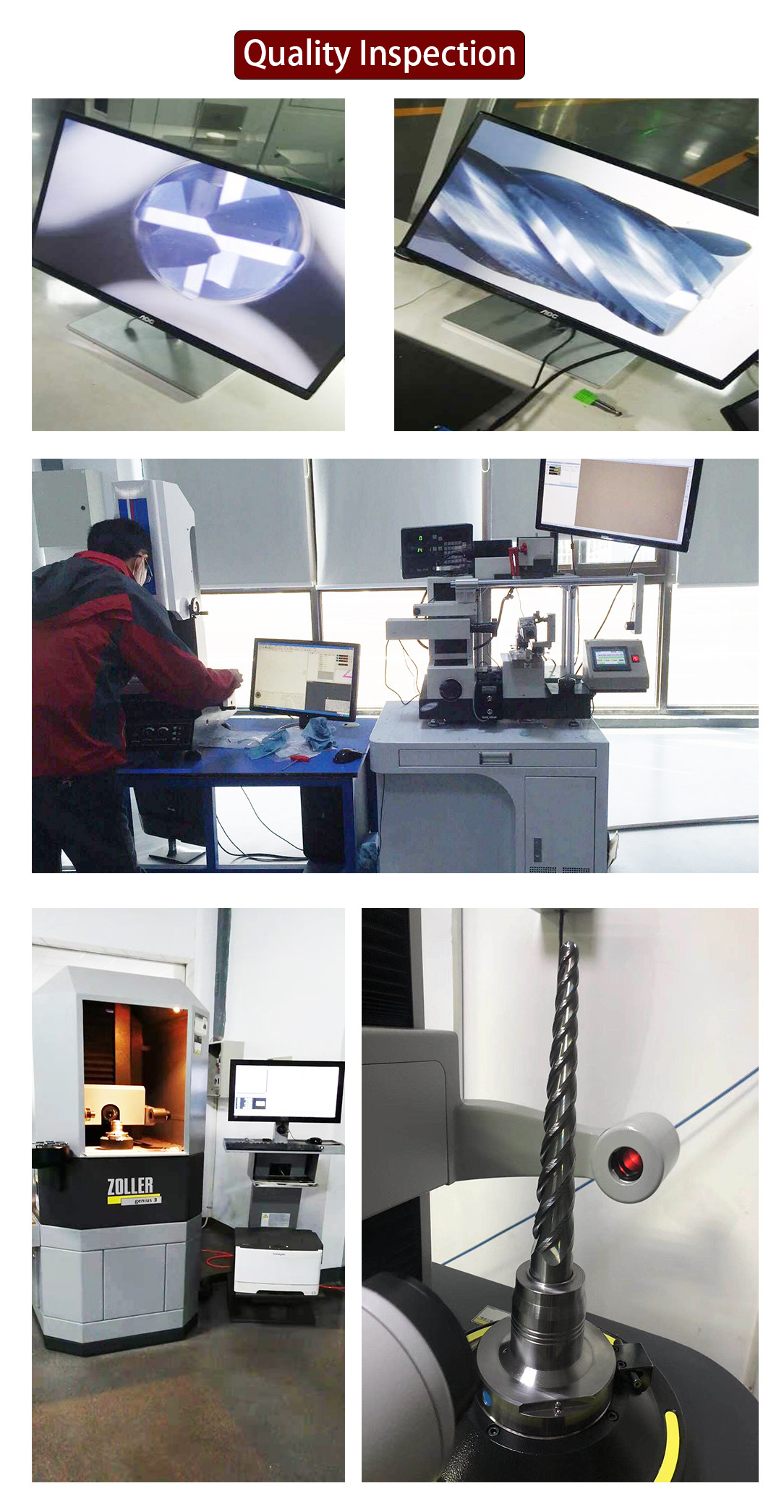

Strict Quality Checking

Check each piece.Guarantee the tolerance -0.02mm

Exact helix angle and finished surface

Goods pass SGS and ISO9001

Exellent Service

Welcome to be our agents, OEM is also available

Customized: It's available according to your drawings or samples

If you have any interest, please contact me at any time at Sales@msutools.com