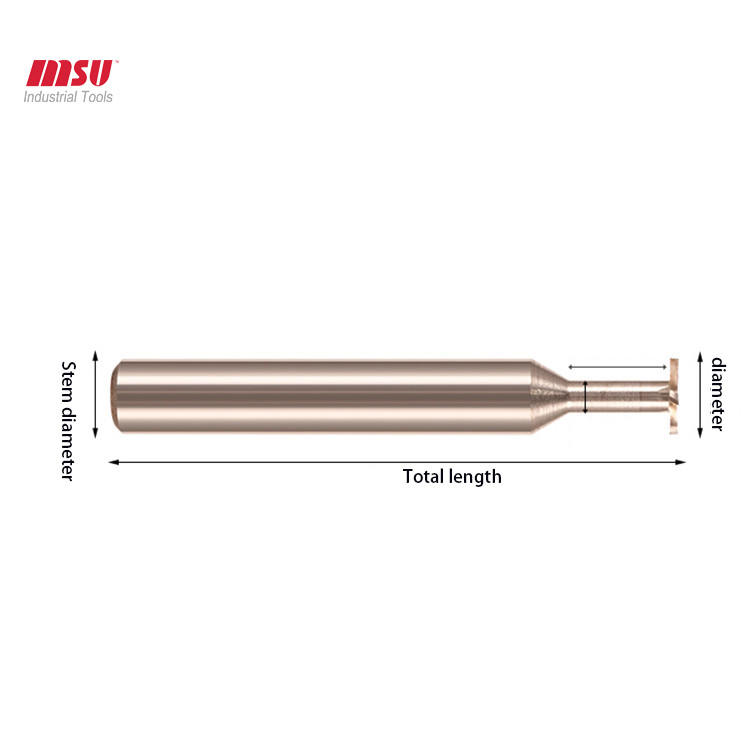

HRC55 4Flutes Uncoated T-Slotting Cutter For Aluminum Alloy

- Model

- D1mm-20mm

Item specifics

- Material

- Solid Carbide

- Internal Cooling

- Without

- No of Cutting Flute

- 4 Flutes

- Type

- Flattened

- Coating

- Uncoated

- Cutting Direction

- Right - Hand

- Helix Angle

- 35°

- Precision

- ±0.01

- Workpiece

- Aluminum/ Copper Alloys/Heat-resistant alloys/Plas

- Application

- Milling

- Cutting Diameter

- 1mm-20mm

- Full Length

- 50mm/75mm/100mm/150mm

Review

Description

2 or 3 Flutes Carbide End Mill For Aluminium

|

Description

|

HRC55 4Flutes Uncoated T-Slotting Cutter For Hard Tungsten Steel And Alloy Aluminum

|

||

|

Hardness

|

HRC58

|

||

|

Coating

|

Uncoated

|

||

|

Helix Angle

|

35°

|

||

Workpiece | Aluminum/ Copper Alloys/Heat-resistant alloys/Plastics | ||

Application | Side Milling and Face Milling/Slotting | ||

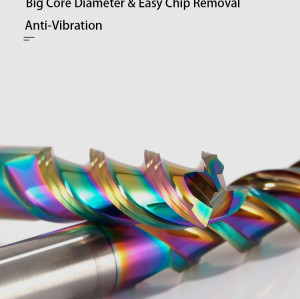

1. Special Cutting Edge: Special cutting edge can increase the cutting. The lifetime of tools and machines will be longer. 2. U shape design:can be suitable for big feed machining. 3. Smooth And Wide Flute: Smooth and wide flute will remove the cuttings more easily. 4. Heat-resistant Coating: With highly heat-resistant HELICA coating, can be used for high-speed processing 5. DLC Coating: can increase lifetime 2-3 times longer 6. High Quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten 7. Polished Surface Treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved | |||

Related Products

Ball Nose End Mill For Aluminium

HRC55

Uncoated(Mirror Finish)

Roughing End Mill For Aluminium

HRC55

Uncoated (Mirror Finish)

Chamfer Mill For Aluminium

HRC55

90°/120°