HRC55- Carbide Corner Radius End Mill

- Model

- D1mm-20mm

Item specifics

- Material

- Solid Carbide

- Internal Cooling

- Without

- No of Cutting Flute

- 4 Flutes /3 Flutes

- Type

- Corner Radius

- Coating

- TiSin

- Cutting Direction

- Right - Hand

- Helix Angle

- 38°

- Precision

- ±0.01

- Workpiece

- Steel/ Alloy Steel/ Cast Iron

- Application

- Milling

- Cutting Diameter

- 4mm - 20mm

- Full Length

- 50mm/75mm/100mm/150mm

Review

Description

MSU Carbide Corner Radius End Mill

|

Description

|

MSU Bull Nose End Mills (Corner Radius) Carbide HRC55 Nano Coated

|

||

|

Hardness

|

HRC55

|

||

|

Coating

|

TiSin Coating

|

||

|

Helix Angle

|

38°

|

||

Workpiece | Steel/Cast Iron | ||

Application | Side Milling and Face Milling/Slotting | ||

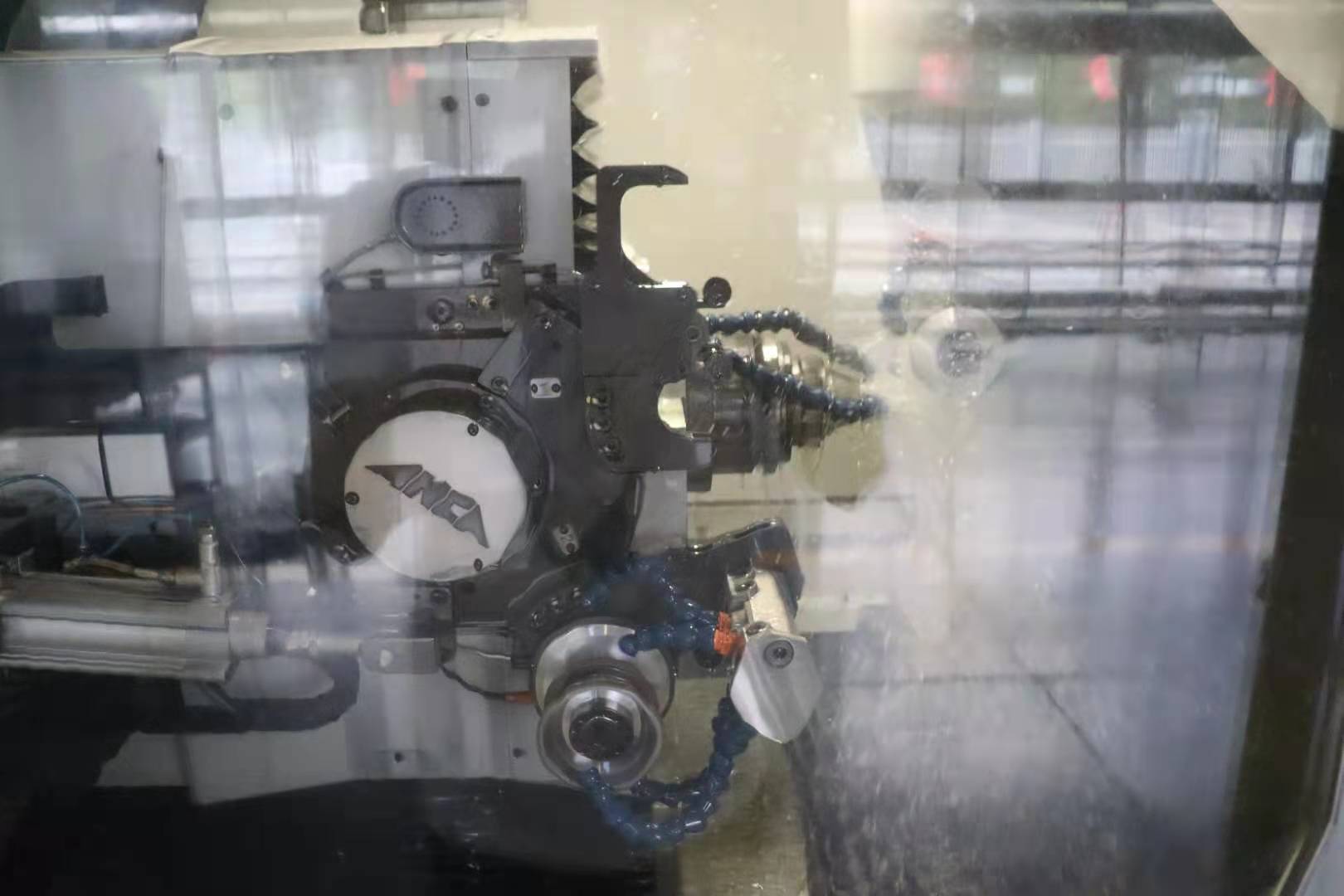

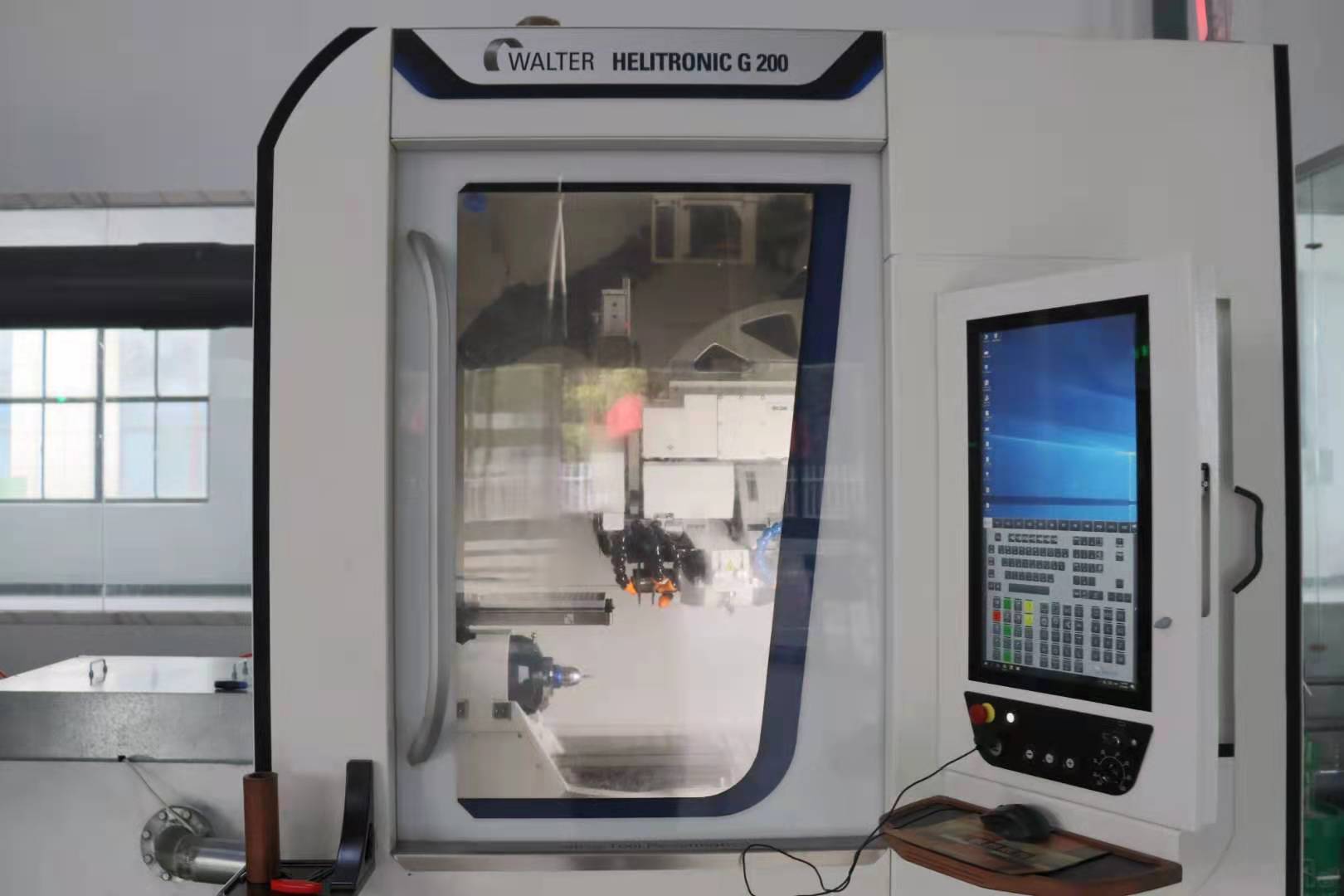

Corner radius end mills or bull end mills are single-ended cutting tools used for making a specific corner radius to a workpiece or to remove a sharp edge or burr in a finishing operation. They are less prone to chipping and generally have a longer tool life. Bull end mills are usually made from carbide steel and are available in various flute counts and helix angle configurations. All End Mills are made by 5 Axis CNC machines such as ANCA/Walter, the end mills come to be high precision, long working life, high efficiency. | |||